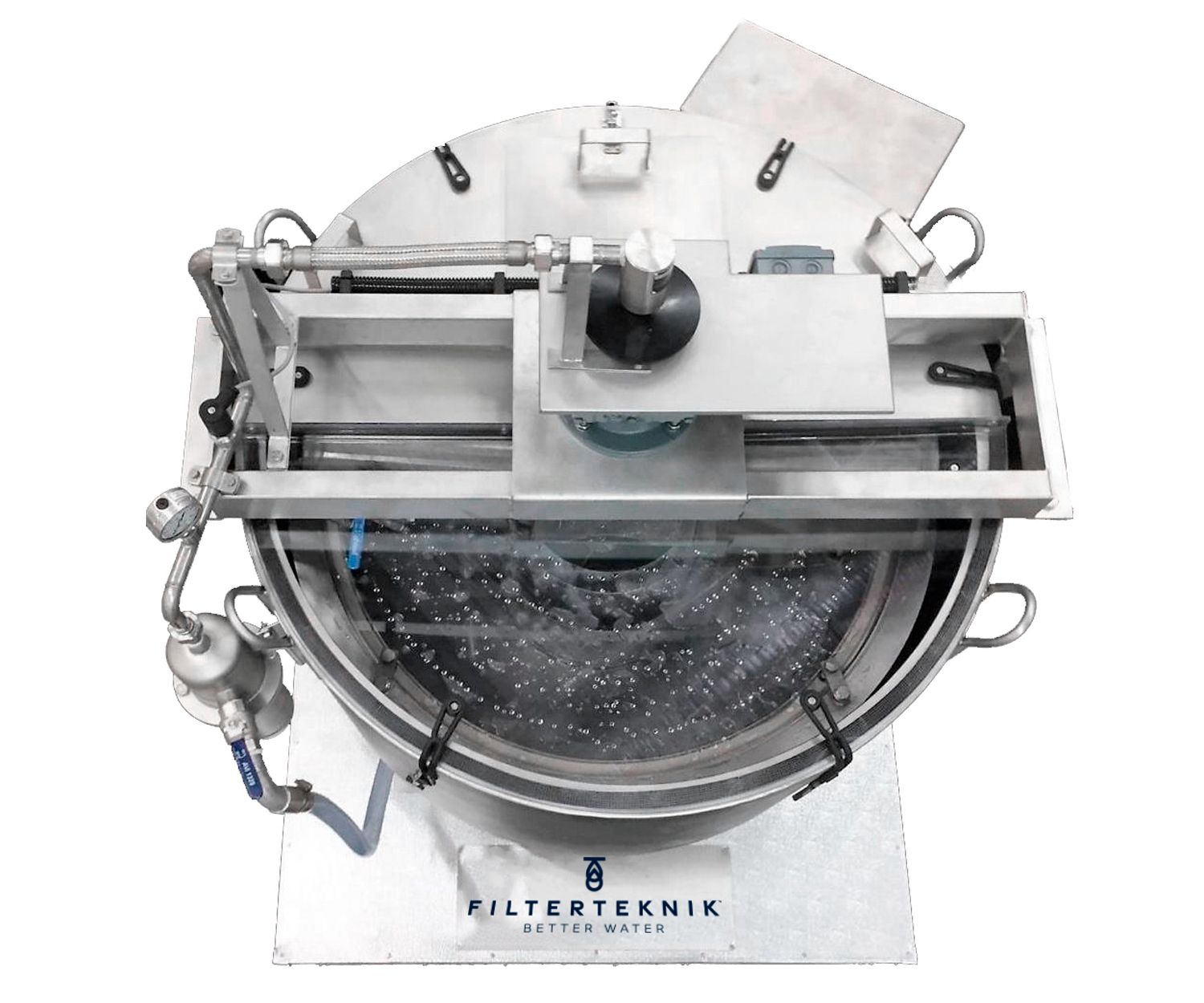

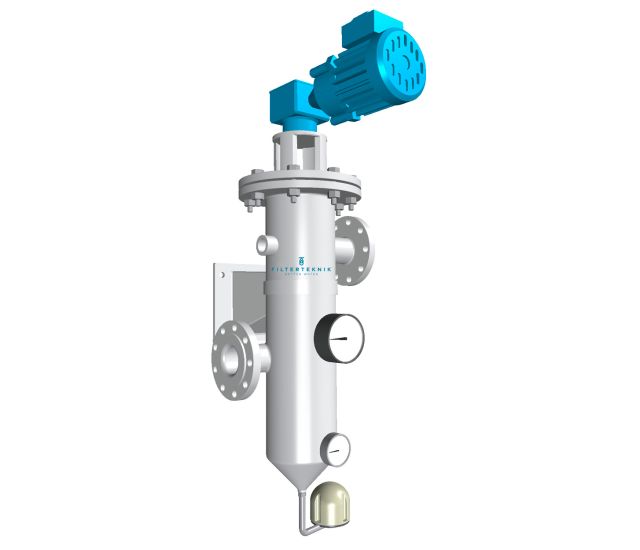

BSW™ Gravity Strainer

For white water and fresh water applications

-

Proven Return on Investment

-

High efficiency and superior cleaning technique

-

Simple design and easy inspection

Gravity Strainer for Paper and Pulp Fibers

Swedish Quality Filters manufactured in Hovmantorp, Sweden

BSW™ Gravity Strainer is designed to strain large amounts of “white water”, water with large amounts of suspended solids. This unit is for application where the concentration and the flows are too high for a pressurised filter.

The filter is used on water streams with 20 up to about 600 mg/l (ppm) fibres. Smaller units are used for up to about 1000 ppm. Typical applications are the mill’s spray water supply, purification of sealing water from vacuum pumps, polishing of water from flocculation plants and cooling towers. The filter is also used for purification of intake water from lakes and rivers.

-

Easy to install, self contained modular unit

-

No trapping or driving solids through screen openings

-

Fibers are continuously removed by bottom up spray showers

-

Performance can be fine tuned for change in concentration or flow rate

-

Small floor space compared to a number of inline strainers

-

Easy visual performance check and infrequent maintenance

-

No long shutdown required for cleaning

BSW™ Gravity Strainer is available in six sizes, has a self cleaning systems that work under atmospheric conditions, removing suspended solids from relatively high flow water streams up to 11000 l/min. They are most commonly used in the pulp and paper industries to reduce the fibre concentration and to remove felt hairs and fibre bundles. Also to separate long fibres and process debris from recycled plant waters.

Superior alternative to top down sprays

-

Lifts fibers/debris off of screen with continuous backwash cleaning

-

Minimizes potential for clogging and chance of fiber stapling over wire

-

Allows a larger mesh than equivalent “top-down” filter

-

No backwash cycle or bag changing

25 to 700 m3/h

0.08 to 0.3mm (80 to 300 micron)

DN100 to DN400

0.25 – 0.37 kW, depending on filter size

Stainless steel EN1.4301 / EN1.4404 / EN1.4436

BSW10, BSW14, BSW17, BSW22, BSW25, BSW30

The water is fed in tangentially between the outer and inner jackets of the filter vessel. The water flows up and over the edge of the internal vessel and down onto the strainer media. Unwanted solids/fibres are captured upon the strainer media, and clean water passes through the fine filter mesh, exiting at the bottom of the strainer vessel. Cleaning is achieved by spray cleaning the strainer media in a novel way, “bottom-up cleaning”. Two spray bars positioned below the strainer media, rotates in-line with the unique collection chambers located directly above the strainer media. These collection chambers catch the fibres/solids lifted by spray water from the screen surface, and feed them down towards the drain. Fibres are transported inside the collection chambers, not on the top of the strainer media.